Project Description

Pope Pinch Bottom bags are made of polypropylene and are 100% recyclable.

- LIGHTER

- STRONGER

- LOW ENVIRONMENTAL FOOTPRINT

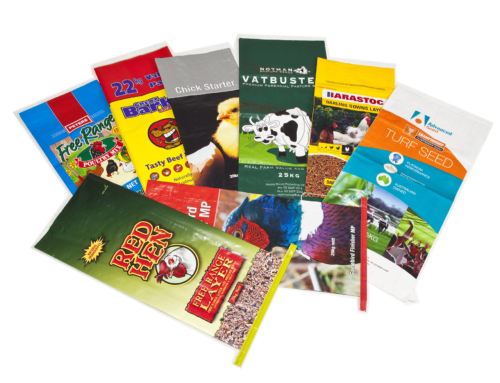

PopePinch bags are made of high strength WPP tape that has been combined with a printed biaxially oriented polypropylene (BOPP). The final product is a high strength lightweight bag with superior tear & puncture resistance and first-class appearance.

PopePinch delivers many advantages over other forms of packaging including:

- Hi-res 8 colour printing for outstanding product presentation and brand recognition

- Woven polypropylene with a BOPP film construction for improved strength and reduced raw material use

- Strong pinch bottom design for improved handling and less risk of breakage

- Easy-open feature

- Suitable for automatic filling systems

- 100% recyclable

PopePinch bags are perfect for retail presentation

The use of BOPP film and Hi-res 8 colour printing of the entire bag, including the bottom, allows brands to be displayed even when the product is presented on a transport pallet. Furthermore, the BOPP film is reverse printed ensuring it is protected against scratches and abrasions during handling, delivering a lasting eye-catching appearance.

The pinch bottom design prevents leaks and moisture penetration.

The pinch bottom closure is glued and seals better than a sewn seam. Also, the BOPP film provides a sound moisture barrier, removing the need for a polyethylene inner liner.

PopePinch bags can be used on existing open mouth filling lines and pinch bag closing lines. Modified regular pinch bag closing lines are perfectly suitable.